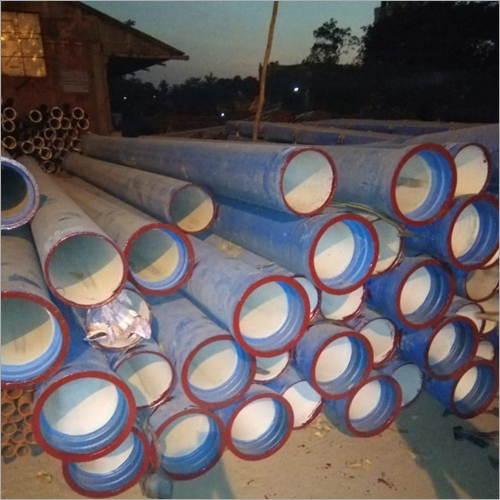

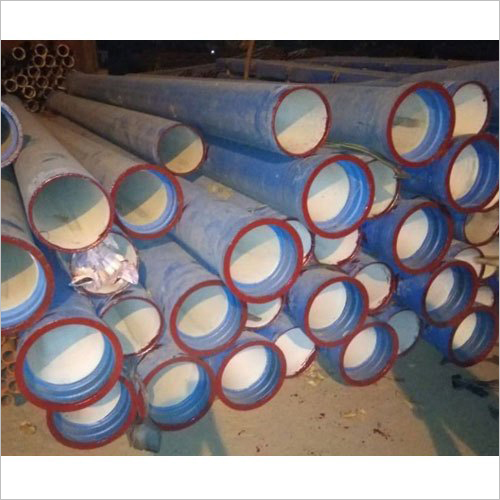

Ductile Iron Pipe With Flanged Ends Is: 8329

Ductile Iron Pipe With Flanged Ends Is: 8329 Specification

- Product Type

- Ductile Cast Iron Pipe

- Material

- Cast Iron

- Shape

- Round

- Standard

- IS 8329

- Diameter

- 100mm (OD) Millimeter (mm)

- Hardness

- Max. 230 BHN

- Color

- Black

- Warranty

- 12 months

Ductile Iron Pipe With Flanged Ends Is: 8329 Trade Information

- Minimum Order Quantity

- 1000 Sets

- Supply Ability

- Set

- Delivery Time

- Week

About Ductile Iron Pipe With Flanged Ends Is: 8329

DUCTILE IRON PIPE WITH FLANGED ENDS CONFORMING TO IS : 8329

Technical details

|

Material |

Ductile Iron |

|

Shape |

Round |

|

Hardness |

Max. 230 BHN |

|

Modulus Of Elasticity |

1.7 x 1010 Kg/M2 |

|

Tensile Strength |

Min. 420 MPa |

|

Surface Finishing |

Powder Coated |

Superior Performance for Industrial Applications

Engineered from high-quality cast iron and meeting IS 8329 standards, our ductile iron pipes offer excellent durability and strength, making them ideal for industrial and municipal water supply systems. The flanged ends facilitate secure connections, ensuring leak-proof installations in demanding environments.

Quality You Can Trust - 12 Months Warranty

Backed by a 12-month manufacturer warranty, these pipes guarantee peace of mind and long-term service. Each pipe is rigorously tested for hardness (max. 230 BHN), corrosion resistance, and overall reliability, providing an assurance of consistent quality to our customers.

FAQs of Ductile Iron Pipe With Flanged Ends Is: 8329:

Q: How is the Ductile Iron Pipe With Flanged Ends produced according to IS 8329 standards?

A: These pipes are manufactured using advanced casting techniques as outlined in IS 8329, ensuring precise dimensions, maximum hardness of 230 BHN, and reliable flanged ends for strong and secure connections.Q: What are the main applications for this 100mm ductile iron pipe?

A: The pipe is primarily used for water supply, sewage, and industrial fluid transportation systems, thanks to its robust construction, corrosion resistance, and easy-to-install flanged ends.Q: When can customers expect delivery of the ductile iron pipes?

A: Delivery timelines depend on your location and order quantity, but as a distributor and supplier based in India, we strive to fulfill most orders within a few business days.Q: Where in India do you supply these flanged ductile iron pipes?

A: We supply and distribute these pipes nationwide, catering to customers in urban and rural areas, including cities and remote regions across India.Q: What is the process for installing pipes with flanged ends?

A: Installation involves aligning the flanged ends with corresponding pipeline sections, securing with bolts and gaskets, and checking for leak-proof joints to ensure reliable operation.Q: How does using this ductile iron pipe benefit my project?

A: You gain superior durability, reduced maintenance costs, and a warranty-backed product that offers dependable performance under harsh operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ductile Iron Pipe Category

Jai Balaji Ductile Iron Pipe

Price 1040 INR / Meter

Minimum Order Quantity : 200

Product Type : Ductile Cast Iron Pipe

Shape : Round

Hardness : Max. 230 BHN

Material : Cast Iron

Ductile Iron Pipe

Price 500 INR / Meter

Minimum Order Quantity : 100

Product Type : Ductile Cast Iron Pipe

Shape : Round

Hardness : Max. 230 BHN

Material : Cast Iron

DI Pipe

Price 1120 INR / Meter

Minimum Order Quantity : 100

Product Type : Ductile Cast Iron Pipe

Shape : Round

Hardness : Max. 230 BHN

Material : Cast Iron

Ductile Iron Pipe With Blue Epoxy Coating

Price 1250 INR

Minimum Order Quantity : 1000

Product Type : Ductile Cast Iron Pipe

Shape : Round

Hardness : Max. 230 BHN

Material : Cast Iron

Send Inquiry

Send Inquiry Send SMS

Send SMS